A Flexible, Customized Platform

To Give You Just What You Need.

The Reveal platform gives you a customized, in-line solution along with

flexibility on how to operate and integrate it. You have choices with Reveal.

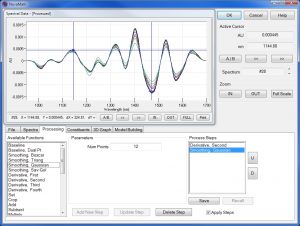

We can build the application modeling for you, or you can build your own.

POWER

AC line power 120-265 VAC, 50/60 Hz

DC Power 24V

Dual hot-swappable batteries

DETECTOR

UV (190-400 nm)

UV/VIS (200-850 nm)

VIS (350-850 nm)

NIR (1550-1950 nm)

Extended NIR (1100-2100 nm)

LIF (280-800 nm)

CONTROLLING INTERFACE/MODELING

NovaPAC/NovaMath – user defined models

Reveal – Internal model

EXTERNAL CONNECTIONS

Measurement interface, industrial

communications, power

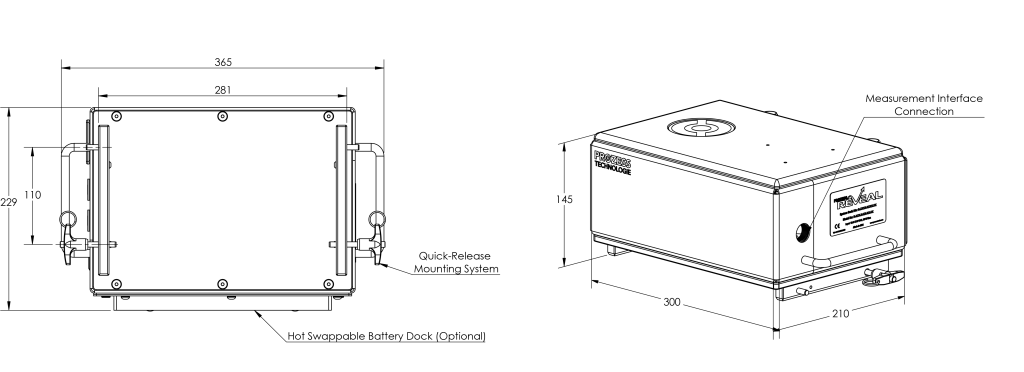

CHASSIS OPTIONS

Quick-release brackets

ATEX

NFPA

Heating, cooling

DIMENSIONS

300 mm x 210 mm x 110 mm

WEIGHT

13 lbs.

CONSTRUCTION MATERIALS

Enclosure: 316 stainless, anodized aluminum

Sample Interface: 316 stainless, sapphire (std.)

Others available as required

MAINTENANCE

Automated calibration/referencing

User replaceable lamp cartridge

(1500+ operating hours)

PROCESS INTERFACES

100’s of reflectance probes,

transflectance probes, flow cells

LIGHT SOURCE

Tungsten halogen lamp

Deuterium lamp

Combo tungsten / deuterium lamp

LED

COMMUNICATIONS

Ethernet, WiFi, Modbus, OPC UA, EtherNet/IP,

expansion port for additional outs

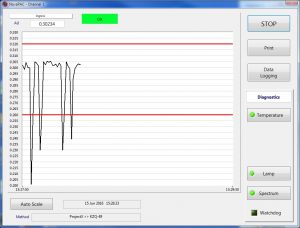

It runs 24/7/365 in any environment without ongoing operator interaction. Our internal calibration hardware allows for stability and reliability.

All Reveal enclosures are IP65 or higher. Hazardous area options are also available.

Dimensional drawings in mm

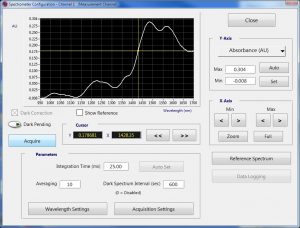

Our fully-integrated software suite handles hardware control and chemometric analysis while ensuring that Reveal remains compliant with the U.S. FDA’s strictest guidelines on electronic records and signatures (21 CFR Part 11), the PAT initiative and Good Automated Manufacturing Practices (GAMP) as well as U.S. and European Pharmacopeia.

Having the right process interface is essential to making any measurement. We have hundreds of different probes that fit in almost any environment:

- Pressure: less than 11,000 psi

- Operating temperature of machine: 0°C to 40°C (in standard packaging)

- Operating temperature of probe: under 400°C

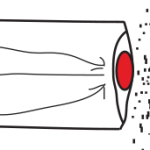

MEASURING HEAD

- Use for non-contact measurement through a window

- LIF, NIR

- For Powders

- For Slurries

- Diffuse Reflectance, Fluorescence

- Variable Working Distance

- IP65 Compliant

CONTACT PROBE

- Use for contact measurement (at the probe tip)

- LIF, NIR For Powders: Diffuse Reflectance, Fluorescence

- For Liquids: Fluorescence

- IP65 Compliant

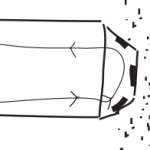

DIP PROBE

- Use for contact measurement via insertion

- UV, VIS, NIR, LIF For Liquids: Trans Reflectance, Transmission

- Multiple Optical Path Lengths Available

- Multiple Probe Sizes Available

ATR PROBE

- Use for contact measurement via insertion

- Excellent for strongly absorbing liquids, viscous liquids

- UV, VIS, NIR, LIF

- For Liquids

- For Slurries

- 3-Bounce ATR Design

- Sapphire Crystal Tip

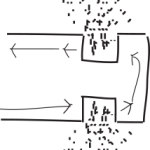

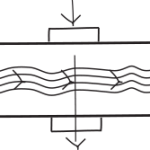

FLOW CELL

- Use for flowing liquids

- UV, VIS, NIR, LIF

- Small Volume to Large Volume Available

- Piping Connections are Full Customizable

- Multiple Optical Path Lengths, Variable Path Available

HEATED PROBE

- Use for contact measurement via insertion

- Excellent for sticky substances; HSWG / Drying

- NIR

- For Powders: Diffuse Reflectance

- Sapphire Window

- Active Control: Heating

PURGED PROBE

- Use for contact measurement via insertion

- Excellent for Drying

- For Powders: Diffuse Reflectance

- Active Control: Compressed Air for Purging, Cleaning

It offers a full line of industrial communications options for easy integration into your control system, including Modbus, OPC and EtherNet/IP. An expansion port allows additional communication options, which is helpful if you want analog outs. There’s also a secured easy access to each Reveal so plant operators with tablets or smartphones can access the instrument in the process line.